Have you ever noticed that subtle, high-pitched squeak as you pull your favorite shade of “super-saver” acrylic through a stitch? Or perhaps you’ve felt that inexplicable drag on a hook that used to glide like butter through silk? You probably brushed it off as a humid day or a tight tension issue. But what if I told you that your yarn basket is actually a weapon? What if that budget-friendly, vibrant acrylic yarn you adore is actually acting as a microscopic sheet of sandpaper, slowly but surely grinding down the life of your most precious tools?

We treat our crochet hooks like lifelong companions. We invest in ergonomic handles, hand-turned resins, and high-grade aluminum or gold-plated finishes. We expect them to be the constant in our creative journey. Yet, the very material we feed them—the ubiquitous petroleum-based plastic we call acrylic—is engaged in a silent war of attrition against them. It’s a dirty secret that the big-box yarn manufacturers won’t put on the label: your yarn is killing your hooks.

The Friction Fallacy: Plastic vs. Metal

To understand the carnage, we have to look at the chemistry of the “squeak.” Acrylic yarn is essentially a polymer. It is plastic. When you run a plastic fiber over a metal or wooden surface thousands of times an hour, you aren’t just moving yarn; you are generating heat through friction. While natural fibers like wool or cotton have a certain level of organic “give” and natural oils (like lanolin), acrylic is a hard, abrasive synthetic.

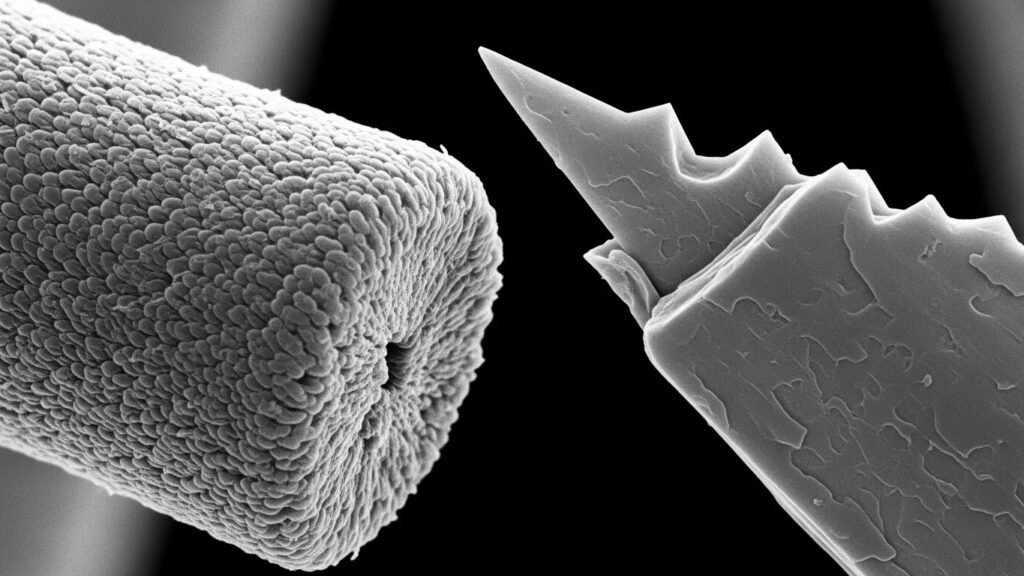

Think about the physics of a single crochet stitch. The yarn wraps around the throat of the hook, slides up the shaft, and is pulled through the loop. Under a microscope, the surface of cheap acrylic is jagged and irregular. Every time you make a stitch, those microscopic plastic teeth are biting into the finish of your hook. Have you ever wondered why the beautiful colored coating on your aluminum hooks eventually wears off, revealing the dull grey metal beneath? That isn’t just “love” or “use.” That is mechanical erosion. Are you okay with your yarn literally eating your tools for breakfast?

The Chemical Leeching: More Than Just Wear and Tear

It isn’t just the physical rubbing that’s the problem. It’s the chemical composition of the yarn itself. Acrylic yarns are often treated with various finishing agents—softeners, flame retardants, and industrial dyes—to make them feel less like the plastic they are. As the friction between the hook and yarn generates heat, these chemicals can undergo a minor breakdown, transferring a microscopic film onto your tool.

This film is the culprit behind that “sticky” feeling. Have you ever cleaned your hook and noticed a greyish, waxy residue on the cloth? That is a mixture of oxidized metal, sloughed-off plastic particles, and chemical finishers. This buildup doesn’t just make the hook look ugly; it changes the diameter of the hook’s throat and shaft. In the world of high-stakes crochet, where gauge is everything, your “favorite” yarn is subtly altering your tool’s dimensions. Is your gauge failing because of your tension, or because your hook has been “thickened” by a layer of industrial waste?

The “Squeak” of Death: Why Your Hook is Screaming

We’ve all joked about the “crochet squeak.” We put on headphones or turn up the TV to drown it out. But that sound is actually a distress signal. In engineering, that sound is known as “stick-slip vibration.” It occurs when two surfaces don’t slide smoothly but instead catch and release in rapid succession.

When your acrylic yarn squeaks, it is because the friction has reached a point where the yarn is literally grabbing the surface of the hook and tearing at it. If you heard that sound coming from your car engine, you’d pull over immediately. Why do we tolerate it in our hands? Over time, this stick-slip action creates “micro-pitting”—tiny holes in the metal or wood that you can’t see with the naked eye but can certainly feel as increased drag. You are turning a professional-grade tool into a jagged piece of scrap metal, one “super-saver” skein at a time.

The Victim List: Bamboo, Wood, and Resin

If you think your expensive hand-carved rosewood or bamboo hooks are safe because they aren’t “coated metal,” think again. In fact, organic hooks are the most vulnerable to the acrylic onslaught. Wood and bamboo are porous. They rely on a smooth, polished surface to function. Acrylic yarn act as a desiccant, stripping away the natural oils and waxes used to finish these hooks.

As the acrylic drags across wood, it raises the grain. You might notice your wooden hooks feeling “fuzzy” or developing small snags after a big project. That is the acrylic fibers physically pulling the wood fibers apart. Once that smooth finish is gone, the hook is effectively ruined. It will snag on everything, especially the very yarn that destroyed it. Is it fair to blame the hook maker for a “cheap” product when you’ve been subjecting a delicate organic material to a plastic sandpaper bath?

The Heat Factor: Melting Your Precision

Let’s talk about speed. Many of us pride ourselves on how fast we can crochet. But speed equals heat. In the manufacturing of synthetic fibers, heat is used to shape and set the plastic. When you crochet at high speeds with acrylic, the friction can actually reach temperatures high enough to cause “micro-melting” of the yarn surface.

This doesn’t mean your yarn will turn into a puddle, but it does mean that the surface of the yarn becomes even more adhesive. This heat speeds up the transfer of plastic polymers to the hook. If you use resin or plastic hooks, this is a recipe for disaster. You are essentially rubbing two similar polymers together under heat and pressure. The “wear” marks you see on plastic hooks—those deep grooves where the yarn sits—are the result of the hook literally being worn down by the faster-moving yarn. You are reshaping your tools with every row. Is your favorite 5.0mm hook actually still a 5.0mm, or has it been “sanded” down to a 4.75mm?

The Ergonomic Nightmare: Your Body is Paying the Price

The damage isn’t just to the hook; it’s to the hand holding it. Because acrylic yarn creates so much more drag and friction than natural fibers, your muscles have to work harder to pull the hook through the loops. You have to grip the hook tighter to overcome the “stick-slip” vibration.

This increased tension in your hand, wrist, and forearm is the leading cause of “crocheter’s cramp” and, eventually, carpal tunnel or tendonitis. We spend hundreds of dollars on ergonomic hooks to save our joints, but then we use a yarn that creates so much resistance that the ergonomics are rendered useless. Are you willing to sacrifice your ability to crochet in ten years just to save five dollars on a skein of yarn today?

The Dying Art of the Hook: A Professional’s Perspective

If you talk to veteran hook makers—the ones who spend hours polishing a single piece of surgical-grade stainless steel—they will tell you that the rise of low-quality acrylic has changed the way they have to design tools. Some have even started using harder, more industrial coatings just to stand up to the “acrylic era.”

We are losing the nuance of fine tools because we are obsessed with cheap materials. A hook designed for the gentle slip of silk or the oily glide of wool can’t survive in an acrylic world. We are forcing our toolmakers to prioritize “armor” over “finesse.” Is this the direction we want our craft to go? Do we want tools that are just durable enough to survive a plastic onslaught, or do we want tools that are masterpieces of balance and slide?

How to Save Your Tools (And Your Sanity)

If you aren’t ready to give up your acrylic stash, how do you mitigate the damage? The answer isn’t just “buying more hooks.” It’s about maintenance and awareness.

First, you must clean your hooks. Not once a year, but after every project. Use a gentle, non-abrasive cleaner to remove the chemical film left by the synthetic fibers. For metal hooks, a drop of high-quality tool oil or even a tiny bit of wax can help restore the glide and provide a protective barrier against the abrasive plastic.

Second, rotate your tools. Don’t use the same hook for five consecutive 100% acrylic blankets. Give the material time to “recover” and give yourself time to notice the wear patterns.

Third, and most importantly, consider the “True Cost” of your yarn. If you save $20 on yarn but destroy a $30 ergonomic hook and spend $200 on physical therapy for your wrist, was the yarn actually a bargain?

The Ethical Dilemma: Plastic in the Hand, Plastic in the Land

Beyond the hook, we have to address the elephant in the room: environmental impact. Every time your hook “sands down” that acrylic yarn, it creates micro-plastic dust. This dust is so fine you probably don’t even see it, but it’s there—on your clothes, in your carpet, and in your lungs. When you wash that acrylic blanket, thousands of micro-fibers enter the water system.

Our tools are showing us the truth that our eyes refuse to see. The wear and tear on your hook is a physical manifestation of the stress that synthetic materials put on our world. Your hook is the “canary in the coal mine.” It is failing because it wasn’t meant to endure a lifetime of rubbing against petroleum.

A Call to Arms (and Hooks)

The next time you reach for that cheap, scratchy skein because the color is “just so perfect,” I want you to look at your hook. Look at the shine on the metal, the smooth grain of the wood, or the perfect clarity of the resin. Ask yourself: “Is this project worth the slow destruction of my favorite tool?”

We are at a crossroads in the fiber arts. We can continue to feed our hooks a diet of abrasive plastic, or we can return to the materials that our tools were originally designed to dance with. We can prioritize the quantity of our output, or the quality of our experience.

The squeak you hear isn’t just a nuisance. It’s a cry for help from a tool that is being overworked and under-appreciated. It’s time to listen. It’s time to treat our hooks with the respect they deserve by giving them fibers that glide, not fibers that grind. Will you be the one to save your hooks, or will you keep crocheting until the metal is thin and your hands can no longer hold the weight of your choices?

The choice is yours. But remember: once the finish is gone, it’s gone forever. Your hook is waiting for you to make the right decision. Don’t let it down.

The Final Glide

In the end, the relationship between a crafter and their tool is sacred. It is the bridge between imagination and reality. By choosing our materials wisely, we don’t just protect a piece of metal or wood; we protect the integrity of our craft. We ensure that our hands can continue to create for decades to come.

So, put down the sandpaper yarn. Pick up something that breathes, something that slides, something that lives. Your hooks—and your wrists—will thank you for it. The magic of crochet shouldn’t be a struggle against friction; it should be a seamless flow of creativity. Let’s bring back the glide.

My name is Sarah Clark, I’m 42 years old and I live in the United States. I created Nova Insightly out of my love for crochet and handmade creativity. Crochet has always been a calming and meaningful part of my life, and over the years it became something I wanted to share with others. Through this blog, I aim to help beginners and enthusiasts feel confident, inspired, and supported as they explore crochet at their own pace. For me, crochet is more than a craft — it’s a way to slow down, create with intention, and enjoy the beauty of handmade work.